Service Manual & Parts List Xerox Phaser 3610 WorkCentre 3615;

This manual is in the PDF format and have detailed Diagrams, pictures and full procedures to diagnose and repair your Xerox.

Video captain tsubasa 1983 sub indo. You can print, zoom or read any diagram, picture or page from this Service Manual & Parts List. Every chapter on this manual is fully detailed and contain all the simulation codes, trouble codes, maintenance procedures, reset procedures, diagnose procedures of Xerox Phaser 3610 WorkCentre 3615. You can find easily everything what do you need.

To see what contain, please read table of contents:

Xerox Workcentre 3115 Service Manual Software

The Xerox WorkCentre 3655 Multifunction Printer Service Manual is part of a multinational service documentation system delivered in the standard Xerox EDOC service manual format. This manual is the primary document used for diagnosing, repairing, maintaining, and troubleshooting these systems. View and Download Xerox WorkCentre 3215 service manual online. WorkCentre 3215 all in one printer pdf manual download. Also for: Workcentre 3225. The Xerox Phaser 3610, WorkCentre 3615 Service Manual is the primary document used for diagnosing, repairing, maintaining, and troubleshooting the printer. Use this manual as your primary resource for understanding the operational characteristics of the printer and all available options. DocuMate 3115 (Scanner Only) To keep any scanner operating properly, certain maintenance should be performed at different stages in the life of the product. Our Customer Service Department is here to help if you have questions. If you know already know what you are looking for, you can find the parts, accessories, and replacement DVDs right here.

1. PRODUCT OVERVIEW

About this Service Manual

Service Manual Revision

Technical Support Information

Manual Terms

Manual Organization

Safety

Power Safety Precautions

Power Source

Disconnecting Power

Electrostatic Discharge (ESD) Precautions

Service Safety Summary

General Guidelines

Warning Labels

Safety Interlocks

Servicing Mechanical Components

Servicing Fuser Components

Printer Location

Operational Guidelines

Printer Supplies

Maintenance Safety

Printer Symbols

Introduction

Phaser 3610 Configurations

WorkCentre 3615 Configurations

Printer Options

Additional Memory

Optional 550-Sheet Feeder (Trays 2, 3, and 4)

External Wireless Network Adapter

Control Panel (3610)

Control Panel Layout (3615)

Operational Modes

Running Mode

Ready Mode

Low Power Mode

Sleep Mode

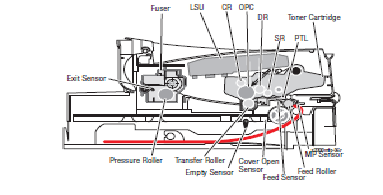

Media Path

Media Path Components

Major Component Locations

Illustration 1 (3610 / 3615)

Illustration 2 (3610 / 3615)

Illustration 3 (3610 / 3615)

Illustration 4 (3610 / 3615)

Illustration 5 (3610 / 3615)

Illustration 6 (3610 / 3615)

Illustration 7 (3610 / 3615)

Illustration 8 (3615 only)

Illustration 9 (3615 only)

Illustration 10 (3615 only)

Illustration 11 (Tray 1)

Illustration 12 (Tray 1)

Information Pages

2. TROUBLESHOOTING

Introduction

Flow of Troubleshooting

Servicing Instructions

Check Installation Status

Initial Actions

Display Problems

Printing Problems

Copy/Scan Problems

DADF Problems

Fax Problems

Media-Based Problems

Multiple-Sheet Pick or MisPick

Skewed Image

Damaged Prints

Wrinkled Envelopes

Fuser Jams

Exit Jams

Service Diagnostics

How To Enter Service Mode

Phaser 3610

WorkCentre 3615

Service Mode Menu Map

Engine Diagnostic Testing

Sensor Test (Digital Output)

Motor Test (Digital Output)

Administration Mode Menu Map

Status Code List (3610)

Status Code List (3615)

Error Code Fault Isolation Procedures (FIP)

Network System Fault Check

Interface (Physical/Logical)

Not connected to network or Unable to find the device from the PC

Printing can be performed but abnormally

Network-related Details Check Flow

Check Flow at SMB Failure

Check Flow at Net Ware Failure

Check Flow at TCP/IP (LPD) Failure

Check Flow at CentreWare Internet Services Failure

3. IMAGE QUALITY

Image Quality Overview

Repeating Defect Measurement

Image Quality Specifications

Environmental Condition

Quality Paper

Paper Condition

Printer Condition

Specifications

Skew

Checklist Before Troubleshooting Image Quality

Check Printer Condition

Toner and Drum Cartridge Status

Cleaning

Operating Environment

Media Condition

Image Quality Troubleshooting

Image Quality Defects

IQ 1 Light Prints

IQ-2 Unfused Image

IQ-3 Random Spots

IQ-4 Blank Print

IQ-5 Streaks

IQ-6 Black Print

IQ-7 Pitched Black Dots

IQ-8 Vertical Bands, Voids, or Streaks (In Paper Feed Direction)

IQ-9 Ghosting

IQ-10 Light Induced Fatigue

IQ-11 Background

IQ-12 Bead Carry-out

IQ-13 Jagged Characters

IQ-14 Banding

IQ-15 Auger Marks

IQ-16 Wrinkled / Stained Paper

IQ-17 Damage to the Lead Edge of the Print

IQ-18 Incorrect Margins

IQ-19 Skewed Image

Printing Test Patterns

Service Diagnostic Mode Test Patterns

Administration Mode Test Patterns

Diagnostics Test Pattern #1 – Pattern IOT

Diagnostics Test Pattern #2 – Gradation ESS

Diagnostics Test Pattern #3 – Ghost Chart ESS

Admin Mode Test Pattern #1 – Pitch Chart

Admin Mode Test Pattern #2 – Alignment Chart

Admin Mode Test Pattern #3 – Full Page Solid

Xerox Workcentre 3115 Service Manual Download

4. DISSASSEMBLY

Overview

Standard Orientation of the Printer

Precautions

Notations in the Disassembly Text

Fastener Types

Covers

REP 1.1 Control Panel (3610)

REP 1.2 Front Cover Assembly (3610 / 3615)

REP 1.3 Top Front Cover (3610)

REP 1.4 Top Cover Assembly (3610)

REP 1.5 Rear Cover Assembly

REP 1.6 Right Side Cover (3610)

REP 1.7 Left Side Cover (3610)

REP 1.8 Lower Rear Cover (3610)

REP 1.9 IIT Left Side Cover

REP 1.10 IIT Front Top Cover

REP 1.11 IIT Front Bottom Cover

REP 1.12 Control Panel (3615)

REP 1.13 Right Side Cover (3615)

REP 1.14 Right Inner Cover (3615)

REP 1.15 Top Cover Assembly (3615)

REP 1.16 Upper Left Side Cover (3615)

REP 1.17 Lower Left Side Cover (3615)

REP 1.18 Lower Rear Cover (3615)

Chassis Repairs

REP 2.1 Duplex Chute Assembly

REP 2.2 Transport Assembly

REP 2.3 Feeder Assembly

REP 2.4 Tray 1 Feed Rollers

REP 2.5 Feed Clutch

REP 2.6 Registration Clutch

REP 2.7 Rubber Registration Roller

REP 2.8 Registration Sensor Shutter

REP 2.9 Tray 1 Stopper

REP 2.10 Rear Interlock Switch Assembly

REP 2.11 Exit Chute Assembly

REP 2.12 Left / Right Pinch Roller

REP 2.13 Full Stack Sensor

REP 2.14 MSI Feed Solenoid

REP 2.15 Pick-up Holder Assembly

REP 2.16 Top Frame Assembly

REP 2.17 Bypass Tray Retard Roller

Xerographic Repairs

REP 3.1 ROS Assembly

REP 3.2 Toner Dispense CRUM Assembly

REP 3.3 Xerographic Connector Assembly

REP 3.4 Transfer Roller Assembly

REP 3.5 Fusing Assembly

Drive Repairs

REP 4.1 Main Drive Assembly

REP 4.2 Exit Output Drive Assembly

REP 4.3 Exit Invert Drive Assembly

REP 4.4 Duplex Drive Gear and Holder

REP 4.5 Front Links

REP 4.6 Dispense Drive Assembly

REP 4.7 Toner Dispense Motor

Electrical Repairs

REP 5.1 ESS PWB

REP 5.2 ESS PWB Housing

REP 5.3 LVPS

REP 5.4 Fax PWB

REP 5.5 Front USB PWB

REP 5.6 MCU PWB

REP 5.7 HVPS (3610)

REP 5.8 HVPS (3615)

REP 5.9 AC Inlet Harness

IIT / DADF Repairs

REP 6.1 IIT Assembly

REP 6.2 DADF

REP 6.3 DADF Hinges

REP 6.4 Pick-up Module Kit

REP 6.5 DADF Tray Assembly

550-Sheet Feeder Repairs

REP 7.1 550-Sheet Feeder

REP 7.2 Left Side Cover

REP 7.3 Right Side Cover

REP 7.4 Rear Cover

REP 7.5 Optional Tray PWB Assembly

REP 7.6 Drive Assembly

REP 7.7 Feed Clutch Assembly

REP 7.8 Feeder Assembly

REP 7.9 No Paper Sensor

REP 7.10 Registration Clutch Assembly

REP 7.11 Feed Roller Assembly

REP 7.12 Retard Roller Assembly

REP 7.13 Pre-Registration Sensor

REP 7.14 Take Away Roller Assembly

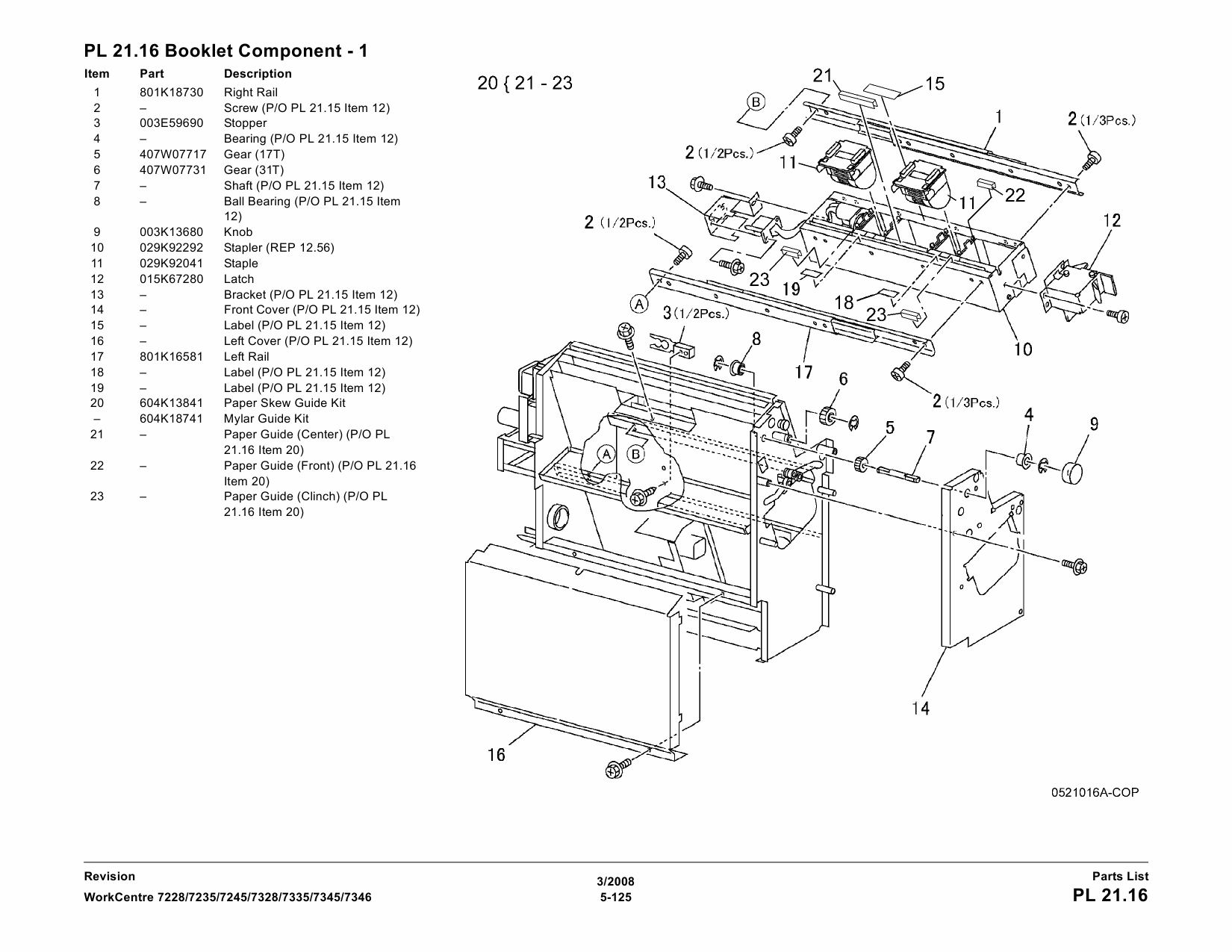

5. PARTS LIST

Serial Number Format

110V Engine Format

Examples

110V Printer

220V Printer

Using the Parts List

Parts Lists

PL 1.1 Covers (3610)

PL 1.2 Covers (3615)

PL 1.3 Rear Cover Assembly

PL 1.4 Control Panel (3610)

PL 1.5 Control Panel (3615)

PL 2.1 Registration

PL 2.2 Transport Assembly

PL 2.3 Feed Assembly

PL 2.4 Duplex Chute

PL 2.5 Exit Chute

PL 2.6 MSI

PL 2.7 Bypass Tray

PL 3.1 Xerographics

PL 3.2 ROS Assembly

PL 3.3 Toner Dispense

PL 3.4 Transfer Roller

PL 3.5 Fusing Assembly

PL 4.1 Drive

PL 4.2 NOHAD

PL 5.1 Electrical (ESS PWB / LVPS) (3610)

PL 5.2 Electrical (ESS PWB / LVPS) (3615)

PL 5.3 Electrical (MCU PWB / HVPS)

PL 5.4 Electrical Connections

PL 6.1 IIT Scanner / DADF

PL 7.1 Tray 1/Optional Tray 550-Sheet Feeder (1/4)

PL 7.2 Tray 1/Optional Tray 550-Sheet Feeder (2/4)

PL 7.3 Tray 1/Optional Tray 550-Sheet Feeder (3/4)

PL 7.4 Tray 1/Optional Tray 550-Sheet Feeder (4/4)

Quick Reference Spares List for the 3610 and 3615

Xerox Supplies

6. MAINTENANCE

Service Maintenance Procedure

Maintenance Safety

Recommended Materials

Repair, Inspect, and Prevent (RIP) Procedure

Cleaning

General Precautions

General Cleaning

Cleaning the Scanner (3615)

Moving the Printers

After moving the printer

Resetting Counters

Resetting the Transfer Unit / Fuser Counters (3610)

Resetting the Transfer Roller / Fuser Assembly Counter (3615)

Adjustments

ADJ 1 Adjusting Paper Type

ADJ 2 Adjusting the Transfer Unit

ADJ 3 Adjusting the Fuser

ADJ 4 Adjusting the Density

ADJ 5 Adjusting Altitude

Firmware Update

Upgrade Procedure

For Network Connections

For USB Connection

Tag Matrix

7. WIRING

Plug/Jack Locations

Plug/Jack Locations for the 3610

Plug/Jack Locations for the 3615

Plug/Jack Locations for Tray 1 and the Optional Feeders

Illustration 01

Illustration 02

Illustration 03

Illustration 04

Illustration 05

Illustration 06

Illustration 07

Illustration 08

Illustration 09

Illustration 10

Illustration 11

Illustration 12

Illustration 13

Wire Harnessing for the Printer

MCU PWB to HVPS / Dispense Motor Assembly

MCU PWB to Xerographic Connector Assembly

MCU PWB to Main Motor Assembly / LVPS

MCU PWB to Optional Feeder Connector

MCU PWB to the ROS Assembly

ROS Assembly to the ESS PWB

MCU PWB to the Full Stack Sensor / Exit Sensor

MCU PWB to the LVPS (1 of 2)

MCU PWB to the LVPS (2 of 2)

MCU PWB to ESS

MCU PWB to the Fusing Assembly

MCU PWB to the Rear Fan Connector

ESS PWB to the LVPS / UI (3610)

ESS PWB to the LVPS / UI (3615)

IIT/DADF Assembly to the ESS PWBA (3615)

ESS PWB to the Front USB (3615)

Wire Harnessing for Option Trays

No Paper Sensor

Optional Tray Pre-Registration Sensor

Optional Tray PWB Assembly (1 of 3)

Optional Tray PWB Assembly (2 of 3)

Optional Tray PWB Assembly (3 of 3)

Notations Used in the Wiring Diagrams

Wiring Diagrams

General Wiring Diagram for 3610

General Wiring Diagram for 3615

1. Power

2. Drive

3. ROS

4. Xerographics / HVPS

5. Fusing

6. Controller (3610)

6. Controller (3615)

7. Scanner

8. Optional Feeder

8. SPECIFICATIONS

Configuration of Printer

System Configuration for the 3610

Functional Configuration

System Configuration for the 3615

Functional Configuration

Electrical Properties

Mechanical Properties

Space Requirements for the 3610

Space Requirements for the 3615

Consumables

Machine Functions

Resolution

Operation Mode

Sleep Mode

Deep Sleep Mode

Machine Status for the 3610

Machine Status for the 3615

Warm-up Time

FPOT (First Print Output Time)

Operating Environment

Safety / Environment Conditions

Print Image Quality

Print Image Quality Guarantee Conditions

Printer Options

ESS Specification

ESS-Supporting OS

Interface Port

Network Protocol

Decomposer

Job Control

Logging

ID Print

Non-Genuine Mode

Cable Characteristics

Communication Load Characteristics

Incoming Call Level

IIT (Image Input Terminal) Specifications (3615)

Scanner

Platen

DADF

FAX Specifications (3615)

FAX Communication

Media Guidelines

Paper Characteristics

Weight

Smoothness

Moisture Content

Grain Direction

Fiber Content

Recommended Paper

Unacceptable Paper

Xerox Workcentre 5330 Manual

- ADF Capacity: 0 sheets (80 g/m2 paper)

- Dimensions: 11.7' x 3.4' x 2.8' (298 x 86 x 71 mm) mm (W×D×H)

- Drivers: TWAIN, WIA

- Duty Cycle: 500 pages/day

- Maximum Paper Size: 216 x 356 (A4) mm

- Interface: USB 2.0 (1.1 compatible)

- Image Enhancement Technology: Visioneer Acuity

- Optical Resolution: 600 dpi

- Output Bit Depth: 24-bit Color, 8-bit Grayscale, 1-bit Bitonal

- Scan Method: Fast Sheefted Duplex and Front Sheetfed

- Supported Operating Systems: Windows 10, 8, 7, Vista, XP (SP2), Mac OS X v10.4 or later

- Visioneer OneTouch Technology: Yes

- Weight: 1.6 Kg

- Speed @ 200dpi, b&w, simplex: 15 ppm

- DocuMate 3115 Scanner

- Power Supply

- USB 2.0 Cable

- Quick Install Card

- Technical Support Card

- Buttons Label

- DVD-ROM including:

- User's Manual

- Nuance OmniPage Pro

- Nuance PaperPort

- Nuance PDF Converter

- Visioneer OneTouch with Acuity technology

- Scanner Drivers (TWAIN, WIA)

Xerox Workcentre 5330 Toner

The Xerox WorkCentre 3655 Multifunction Printer Service Manual is part of a multinational service documentation system delivered in the standard Xerox EDOC service manual format. This manual is the primary document used for diagnosing, repairing, maintaining, and troubleshooting these systems. View and Download Xerox WorkCentre 3215 service manual online. WorkCentre 3215 all in one printer pdf manual download. Also for: Workcentre 3225. The Xerox Phaser 3610, WorkCentre 3615 Service Manual is the primary document used for diagnosing, repairing, maintaining, and troubleshooting the printer. Use this manual as your primary resource for understanding the operational characteristics of the printer and all available options. DocuMate 3115 (Scanner Only) To keep any scanner operating properly, certain maintenance should be performed at different stages in the life of the product. Our Customer Service Department is here to help if you have questions. If you know already know what you are looking for, you can find the parts, accessories, and replacement DVDs right here.

1. PRODUCT OVERVIEW

About this Service Manual

Service Manual Revision

Technical Support Information

Manual Terms

Manual Organization

Safety

Power Safety Precautions

Power Source

Disconnecting Power

Electrostatic Discharge (ESD) Precautions

Service Safety Summary

General Guidelines

Warning Labels

Safety Interlocks

Servicing Mechanical Components

Servicing Fuser Components

Printer Location

Operational Guidelines

Printer Supplies

Maintenance Safety

Printer Symbols

Introduction

Phaser 3610 Configurations

WorkCentre 3615 Configurations

Printer Options

Additional Memory

Optional 550-Sheet Feeder (Trays 2, 3, and 4)

External Wireless Network Adapter

Control Panel (3610)

Control Panel Layout (3615)

Operational Modes

Running Mode

Ready Mode

Low Power Mode

Sleep Mode

Media Path

Media Path Components

Major Component Locations

Illustration 1 (3610 / 3615)

Illustration 2 (3610 / 3615)

Illustration 3 (3610 / 3615)

Illustration 4 (3610 / 3615)

Illustration 5 (3610 / 3615)

Illustration 6 (3610 / 3615)

Illustration 7 (3610 / 3615)

Illustration 8 (3615 only)

Illustration 9 (3615 only)

Illustration 10 (3615 only)

Illustration 11 (Tray 1)

Illustration 12 (Tray 1)

Information Pages

2. TROUBLESHOOTING

Introduction

Flow of Troubleshooting

Servicing Instructions

Check Installation Status

Initial Actions

Display Problems

Printing Problems

Copy/Scan Problems

DADF Problems

Fax Problems

Media-Based Problems

Multiple-Sheet Pick or MisPick

Skewed Image

Damaged Prints

Wrinkled Envelopes

Fuser Jams

Exit Jams

Service Diagnostics

How To Enter Service Mode

Phaser 3610

WorkCentre 3615

Service Mode Menu Map

Engine Diagnostic Testing

Sensor Test (Digital Output)

Motor Test (Digital Output)

Administration Mode Menu Map

Status Code List (3610)

Status Code List (3615)

Error Code Fault Isolation Procedures (FIP)

Network System Fault Check

Interface (Physical/Logical)

Not connected to network or Unable to find the device from the PC

Printing can be performed but abnormally

Network-related Details Check Flow

Check Flow at SMB Failure

Check Flow at Net Ware Failure

Check Flow at TCP/IP (LPD) Failure

Check Flow at CentreWare Internet Services Failure

3. IMAGE QUALITY

Image Quality Overview

Repeating Defect Measurement

Image Quality Specifications

Environmental Condition

Quality Paper

Paper Condition

Printer Condition

Specifications

Skew

Checklist Before Troubleshooting Image Quality

Check Printer Condition

Toner and Drum Cartridge Status

Cleaning

Operating Environment

Media Condition

Image Quality Troubleshooting

Image Quality Defects

IQ 1 Light Prints

IQ-2 Unfused Image

IQ-3 Random Spots

IQ-4 Blank Print

IQ-5 Streaks

IQ-6 Black Print

IQ-7 Pitched Black Dots

IQ-8 Vertical Bands, Voids, or Streaks (In Paper Feed Direction)

IQ-9 Ghosting

IQ-10 Light Induced Fatigue

IQ-11 Background

IQ-12 Bead Carry-out

IQ-13 Jagged Characters

IQ-14 Banding

IQ-15 Auger Marks

IQ-16 Wrinkled / Stained Paper

IQ-17 Damage to the Lead Edge of the Print

IQ-18 Incorrect Margins

IQ-19 Skewed Image

Printing Test Patterns

Service Diagnostic Mode Test Patterns

Administration Mode Test Patterns

Diagnostics Test Pattern #1 – Pattern IOT

Diagnostics Test Pattern #2 – Gradation ESS

Diagnostics Test Pattern #3 – Ghost Chart ESS

Admin Mode Test Pattern #1 – Pitch Chart

Admin Mode Test Pattern #2 – Alignment Chart

Admin Mode Test Pattern #3 – Full Page Solid

Xerox Workcentre 3115 Service Manual Download

4. DISSASSEMBLY

Overview

Standard Orientation of the Printer

Precautions

Notations in the Disassembly Text

Fastener Types

Covers

REP 1.1 Control Panel (3610)

REP 1.2 Front Cover Assembly (3610 / 3615)

REP 1.3 Top Front Cover (3610)

REP 1.4 Top Cover Assembly (3610)

REP 1.5 Rear Cover Assembly

REP 1.6 Right Side Cover (3610)

REP 1.7 Left Side Cover (3610)

REP 1.8 Lower Rear Cover (3610)

REP 1.9 IIT Left Side Cover

REP 1.10 IIT Front Top Cover

REP 1.11 IIT Front Bottom Cover

REP 1.12 Control Panel (3615)

REP 1.13 Right Side Cover (3615)

REP 1.14 Right Inner Cover (3615)

REP 1.15 Top Cover Assembly (3615)

REP 1.16 Upper Left Side Cover (3615)

REP 1.17 Lower Left Side Cover (3615)

REP 1.18 Lower Rear Cover (3615)

Chassis Repairs

REP 2.1 Duplex Chute Assembly

REP 2.2 Transport Assembly

REP 2.3 Feeder Assembly

REP 2.4 Tray 1 Feed Rollers

REP 2.5 Feed Clutch

REP 2.6 Registration Clutch

REP 2.7 Rubber Registration Roller

REP 2.8 Registration Sensor Shutter

REP 2.9 Tray 1 Stopper

REP 2.10 Rear Interlock Switch Assembly

REP 2.11 Exit Chute Assembly

REP 2.12 Left / Right Pinch Roller

REP 2.13 Full Stack Sensor

REP 2.14 MSI Feed Solenoid

REP 2.15 Pick-up Holder Assembly

REP 2.16 Top Frame Assembly

REP 2.17 Bypass Tray Retard Roller

Xerographic Repairs

REP 3.1 ROS Assembly

REP 3.2 Toner Dispense CRUM Assembly

REP 3.3 Xerographic Connector Assembly

REP 3.4 Transfer Roller Assembly

REP 3.5 Fusing Assembly

Drive Repairs

REP 4.1 Main Drive Assembly

REP 4.2 Exit Output Drive Assembly

REP 4.3 Exit Invert Drive Assembly

REP 4.4 Duplex Drive Gear and Holder

REP 4.5 Front Links

REP 4.6 Dispense Drive Assembly

REP 4.7 Toner Dispense Motor

Electrical Repairs

REP 5.1 ESS PWB

REP 5.2 ESS PWB Housing

REP 5.3 LVPS

REP 5.4 Fax PWB

REP 5.5 Front USB PWB

REP 5.6 MCU PWB

REP 5.7 HVPS (3610)

REP 5.8 HVPS (3615)

REP 5.9 AC Inlet Harness

IIT / DADF Repairs

REP 6.1 IIT Assembly

REP 6.2 DADF

REP 6.3 DADF Hinges

REP 6.4 Pick-up Module Kit

REP 6.5 DADF Tray Assembly

550-Sheet Feeder Repairs

REP 7.1 550-Sheet Feeder

REP 7.2 Left Side Cover

REP 7.3 Right Side Cover

REP 7.4 Rear Cover

REP 7.5 Optional Tray PWB Assembly

REP 7.6 Drive Assembly

REP 7.7 Feed Clutch Assembly

REP 7.8 Feeder Assembly

REP 7.9 No Paper Sensor

REP 7.10 Registration Clutch Assembly

REP 7.11 Feed Roller Assembly

REP 7.12 Retard Roller Assembly

REP 7.13 Pre-Registration Sensor

REP 7.14 Take Away Roller Assembly

5. PARTS LIST

Serial Number Format

110V Engine Format

Examples

110V Printer

220V Printer

Using the Parts List

Parts Lists

PL 1.1 Covers (3610)

PL 1.2 Covers (3615)

PL 1.3 Rear Cover Assembly

PL 1.4 Control Panel (3610)

PL 1.5 Control Panel (3615)

PL 2.1 Registration

PL 2.2 Transport Assembly

PL 2.3 Feed Assembly

PL 2.4 Duplex Chute

PL 2.5 Exit Chute

PL 2.6 MSI

PL 2.7 Bypass Tray

PL 3.1 Xerographics

PL 3.2 ROS Assembly

PL 3.3 Toner Dispense

PL 3.4 Transfer Roller

PL 3.5 Fusing Assembly

PL 4.1 Drive

PL 4.2 NOHAD

PL 5.1 Electrical (ESS PWB / LVPS) (3610)

PL 5.2 Electrical (ESS PWB / LVPS) (3615)

PL 5.3 Electrical (MCU PWB / HVPS)

PL 5.4 Electrical Connections

PL 6.1 IIT Scanner / DADF

PL 7.1 Tray 1/Optional Tray 550-Sheet Feeder (1/4)

PL 7.2 Tray 1/Optional Tray 550-Sheet Feeder (2/4)

PL 7.3 Tray 1/Optional Tray 550-Sheet Feeder (3/4)

PL 7.4 Tray 1/Optional Tray 550-Sheet Feeder (4/4)

Quick Reference Spares List for the 3610 and 3615

Xerox Supplies

6. MAINTENANCE

Service Maintenance Procedure

Maintenance Safety

Recommended Materials

Repair, Inspect, and Prevent (RIP) Procedure

Cleaning

General Precautions

General Cleaning

Cleaning the Scanner (3615)

Moving the Printers

After moving the printer

Resetting Counters

Resetting the Transfer Unit / Fuser Counters (3610)

Resetting the Transfer Roller / Fuser Assembly Counter (3615)

Adjustments

ADJ 1 Adjusting Paper Type

ADJ 2 Adjusting the Transfer Unit

ADJ 3 Adjusting the Fuser

ADJ 4 Adjusting the Density

ADJ 5 Adjusting Altitude

Firmware Update

Upgrade Procedure

For Network Connections

For USB Connection

Tag Matrix

7. WIRING

Plug/Jack Locations

Plug/Jack Locations for the 3610

Plug/Jack Locations for the 3615

Plug/Jack Locations for Tray 1 and the Optional Feeders

Illustration 01

Illustration 02

Illustration 03

Illustration 04

Illustration 05

Illustration 06

Illustration 07

Illustration 08

Illustration 09

Illustration 10

Illustration 11

Illustration 12

Illustration 13

Wire Harnessing for the Printer

MCU PWB to HVPS / Dispense Motor Assembly

MCU PWB to Xerographic Connector Assembly

MCU PWB to Main Motor Assembly / LVPS

MCU PWB to Optional Feeder Connector

MCU PWB to the ROS Assembly

ROS Assembly to the ESS PWB

MCU PWB to the Full Stack Sensor / Exit Sensor

MCU PWB to the LVPS (1 of 2)

MCU PWB to the LVPS (2 of 2)

MCU PWB to ESS

MCU PWB to the Fusing Assembly

MCU PWB to the Rear Fan Connector

ESS PWB to the LVPS / UI (3610)

ESS PWB to the LVPS / UI (3615)

IIT/DADF Assembly to the ESS PWBA (3615)

ESS PWB to the Front USB (3615)

Wire Harnessing for Option Trays

No Paper Sensor

Optional Tray Pre-Registration Sensor

Optional Tray PWB Assembly (1 of 3)

Optional Tray PWB Assembly (2 of 3)

Optional Tray PWB Assembly (3 of 3)

Notations Used in the Wiring Diagrams

Wiring Diagrams

General Wiring Diagram for 3610

General Wiring Diagram for 3615

1. Power

2. Drive

3. ROS

4. Xerographics / HVPS

5. Fusing

6. Controller (3610)

6. Controller (3615)

7. Scanner

8. Optional Feeder

8. SPECIFICATIONS

Configuration of Printer

System Configuration for the 3610

Functional Configuration

System Configuration for the 3615

Functional Configuration

Electrical Properties

Mechanical Properties

Space Requirements for the 3610

Space Requirements for the 3615

Consumables

Machine Functions

Resolution

Operation Mode

Sleep Mode

Deep Sleep Mode

Machine Status for the 3610

Machine Status for the 3615

Warm-up Time

FPOT (First Print Output Time)

Operating Environment

Safety / Environment Conditions

Print Image Quality

Print Image Quality Guarantee Conditions

Printer Options

ESS Specification

ESS-Supporting OS

Interface Port

Network Protocol

Decomposer

Job Control

Logging

ID Print

Non-Genuine Mode

Cable Characteristics

Communication Load Characteristics

Incoming Call Level

IIT (Image Input Terminal) Specifications (3615)

Scanner

Platen

DADF

FAX Specifications (3615)

FAX Communication

Media Guidelines

Paper Characteristics

Weight

Smoothness

Moisture Content

Grain Direction

Fiber Content

Recommended Paper

Unacceptable Paper

Xerox Workcentre 5330 Manual

- ADF Capacity: 0 sheets (80 g/m2 paper)

- Dimensions: 11.7' x 3.4' x 2.8' (298 x 86 x 71 mm) mm (W×D×H)

- Drivers: TWAIN, WIA

- Duty Cycle: 500 pages/day

- Maximum Paper Size: 216 x 356 (A4) mm

- Interface: USB 2.0 (1.1 compatible)

- Image Enhancement Technology: Visioneer Acuity

- Optical Resolution: 600 dpi

- Output Bit Depth: 24-bit Color, 8-bit Grayscale, 1-bit Bitonal

- Scan Method: Fast Sheefted Duplex and Front Sheetfed

- Supported Operating Systems: Windows 10, 8, 7, Vista, XP (SP2), Mac OS X v10.4 or later

- Visioneer OneTouch Technology: Yes

- Weight: 1.6 Kg

- Speed @ 200dpi, b&w, simplex: 15 ppm

- DocuMate 3115 Scanner

- Power Supply

- USB 2.0 Cable

- Quick Install Card

- Technical Support Card

- Buttons Label

- DVD-ROM including:

- User's Manual

- Nuance OmniPage Pro

- Nuance PaperPort

- Nuance PDF Converter

- Visioneer OneTouch with Acuity technology

- Scanner Drivers (TWAIN, WIA)